Nc Code Simulator

5 Ways G-Code Simulators Test Your CNC Programs You Don’t Run G-Code Without Testing It, Do You? Use a G-Code Simulator! Mugen 2d Fighting Game. Considering what can happen if there’s a mistake in the gcode, and even CAM software makes mistakes sometimes, you want to test your gcode before you run it to make chips. Testing it can range from “cutting air” to using a G-Code Simulator. “Cutting Air” just means running with part zero set high above the workpiece so the cutter (hopefully) doesn’t come in contact with any material until you see what it will do.

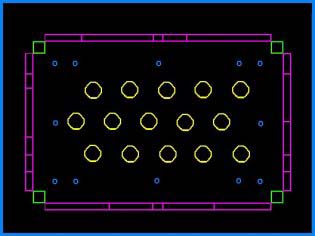

CNC G-Code Simulator ICAM’s Virtual Machine. Get even more efficient NC Code in less time by adopting the unique Adaptive Post-Processing technology. CNCSimulator.com - the best free CNC Simulation software on the planet.Download the free famous CNC Simulator from CNCSimulator.com. The simulator simulates CNC. CNC Machine Simulation detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets. Complex NC code. View, backplot, and simulate your GCode files online, all from within your browser. NC viewer is a free online utitily for verifying and viewing CNC machine gcode files.

Cutting Air is the least you should do to test (also referred to as “proving out” a part program) your gcode part program. The trouble with Cutting Air is it can be very time consuming and it ties up your expensive CNC machine the whole time. What if there was a better way to get a second opinion and test your gcode?

One that didn’t tie up the machine and that could be done much more quickly than Cutting Air. That’s what G-Code Simulators are for. It’s actually cheap and easy to run a G-Code Simulation. You need a piece of software that has variously been called a G-Code Simulator, CNC Backplot,. You’ll also hear the terms “Verification”, “Emulation”, and “Virtual CNC” batted around, though they’re a little less common than the other three. CNC Verification can sometimes have a little different meaning, referring to the high end of the market for this kind of software, so let’s leave it to talk about until the end.

Meanwhile, let’s take a look at CNC Simulation Software, and we’ll use that name for the rest of the tutorial. Here are 5 Ways a G-Code Simulator Can Help Test Your CNC Programs: 1. Backplot: A quick visual indication of what motions the program will make with the cutter. 2.: Checks to make sure the cutter will stay within the area you want it in.

Alarm Checks: The backplot might look okay, but your program can still immediately alarm out on the machine. A good simulator will make many of the same tests as your machine controller ahead of time.

For example, the if the distance from each endpoint to the center of an arc is not the same within a tolerance, you’ll get an alarm. Tooling Summary: A good simulator will compile information about the tools or cutters required by the program. Checking over this list and making sure the right tools are loaded into the machine’s toolchanger is a great test to avoid errors. Subprogram and Macro Tests: A good simulator collects all sorts of information about macros, subprograms, and the variables that are in use. This information can often turn up various problems the part program may encounter. What is a G-Code Simulator? Think of a (or cnc simulator if you prefer) as a piece of software that can execute g-code programs, but instead of controlling servo motors and a spindle on a machine, a g-code simulator produces a graphical display of what the machine would do.